Historian Tristan E. Revells “rebuilds” a biofuel factory from Republican era China through a digital renovation in this virtual museum.

During the early to mid-1930s, the KMT government began supporting scientific research on ethanol-based biofuel production as a means of preserving fuel supplies should imperial Japan successfully blockade supply routes into the country during wartime. As exactly this scenario came to pass in the late 1930s, a network of more than 200 private and state run ethanol plants were constructed alongside new roadworks in the country’s southwestern interior. Between 1938 to 1942, metalworkers, rice wine brewers, technicians, and engineers in many cases improvised and reverse engineered boilers and distillation columns from blueprints, making do with modified and self-forged factory equipment, as well as inventing conversion kits for the fuel lines of vehicle fleets. By 1945, millions of gallons a year of ethanol-based “dongli jiujing” fueled the logistical chains of both Chinese and US troops stationed throughout the China theater.

This is my reconstruction of one wartime ethanol factory.

Tristan E. Revells

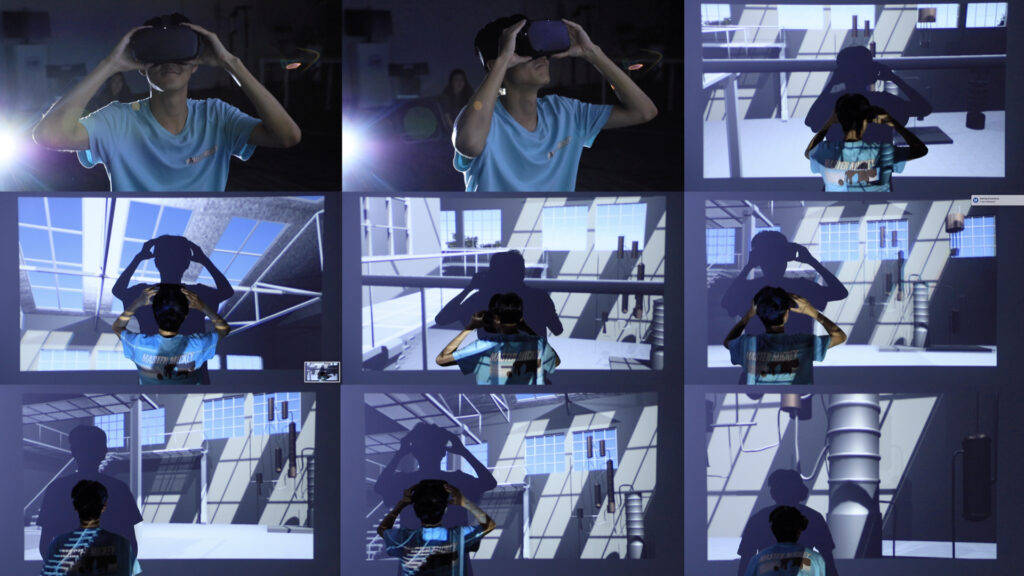

TER: I’m a historian of modern China, with a focus on industrial history and the history of science and technology. The project I’m sharing is a virtual museum detailing the development of a biofuel industry in Republican era China. [Fig 1] In combination with archival sources, I use 3D modeling techniques and VR development tools to create a walkthrough of the industrial system used to generate what was known as dongli jiujing 动力酒精 or “power alcohol” in the 1930s and 40s.

Once in Chongqing, what surprised me was that I was coming out of the archive with all of these elaborate visual sources: diagrams of machinery partially imported from abroad and partially self-forged in China, and blueprints of very complex, elaborate factories and industrial systems–basically, something that Charles Sheeler would have dreamed up [Fig 3].

But I was also aware that beneath all the concrete and shiny steel beams, the government scientists working on the program were in fact adapting microbe-based fermentation methods that Chinese brewers had used for centuries, and then pairing these extant techniques with recent advances in distillation technology to produce ethanol quickly and cheaply. So I had this vague idea that I would have one chapter basically about the technological fusion that sort of preceded the rise of these ethanol factories.

The real problem was that I didn’t have a good way of boiling things down into an explanation of a couple minutes that could translate well outside the confines of the printed page. I went through presentations where I’d basically spend the first 15-20 minutes getting the ins and outs of the sort of technical innovations that were being done in the early 20th century and I would lose everybody’s interest. So what pushed me to develop this digital project was feeling frustrated at my inability to succinctly explain something that would be much more intuitive if the audience had the chance to interact with and see in its original setting.

TER: The reason I decided to build a digital museum was my background in the creative coding community, which I was introduced to around 2010. The CC community conceptualizes coding not as something designed purely for utility (i.e. software engineering), but as something that can extend the range of mediums and formats within which artists, museum designers, academics, and so on can work.

teamLab is perhaps the best known practitioner of this approach, but there are literally thousands of “creative technologists”, “digital artists”, and so on who have been entering the field over the last decade or so. And that’s reflected in the popularity of new media centers like MIT Media Lab and NYU’s Interactive Telecommunications Program and other digital labs at major art and design schools. That said, it’s an area that hasn’t really crossed over into the digital humanities yet, so I think there’s a lot of room for historians to explore the toolkits used by CC practitioners.

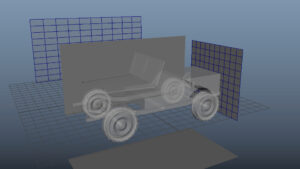

TER: First, you need reference images. I started with archival photos, blueprints, and lists of factory equipment, and then supplemented these with technical manuals and industrial journals from digital databases. You then take these two to three reference images and put them on a coordinate plane. So for instance, here we have an X,Y, and Z axis. [Fig 5] Each of these gray panels would have an image from my archive mapped over and then I can build out for example, these wheels, the undergirding of the chassis, the windshield and so on. And then once I have something roughly approximating the original, I start getting more detailed, adding animations and so on.

In this case, you’ll see in the cross section built to the side of the distiller, you have this series of tubes and basically the way the distillation process works is that steam is pumped from the base of the tube up to the top. And basically based on boiling point, alcohol is carried through the tube up into the next stage of the process, while water and a bunch of other byproducts are left condensing on these small cups within the tube. So that’s like one example of how using 3d modeling allows you to give a visual example that really lets the viewer get to the point rather than, you know, taking several minutes to explain these details.

The next step is to take the 3D models and import them into what’s called a game engine. A game engine is a developing environment that helps you to program in lighting effects, animation, sound, and even a sense of physics to surround your models. In short, it’s what allows a viewer to put on a VR headset and feel immersed in an environment. [Fig 7]

By aiming to make the presentation of this hybrid system interactive, you can immediately engage the viewer’s interest and cut through the fact that you’re talking about something technical and possibly irrelevant. Because I think in many cases, the visual sources themselves are very striking, and it’s a shame to take attention away from them. That said, it’s in appreciating some of these technical details that you really start to understand and appreciate the kind of achievements some of the hybrid innovations represented in this biofuel program. So I’d prefer to let the viewer explore the factory environment on their own terms, and decide for themselves what level of technical detail they care to delve into.

TRISTAN E. REVELLS is an active member of the creative coding community. His most recent work is a digital humanities project initiated at the Science History Institute which uses 3D modeling software to rebuild China’s first large-scale ethanol plant from archival blueprints and photographs. As a historian of the renewable energy industry in China. His dissertation focuses on the dongli jiujing biofuel program of the late 1930s and 40s, an alternative fuel program which emerged from the research of Chinese and Japanese biochemists and microbiologists in the late Qing and early Republican era.

© 2024 positions editorial collective. all rights reserved.